Industrial chillers function to the principles of vapor compression or absorption technological innovation. They can be especially engineered to offer a continuous source of coolant to keep up wanted temperatures.

Centrifugal industrial chillers hire compression to rework kinetic Electrical power into static Power, thus escalating the temperature and force from the refrigerant. The impeller blades attract while in the refrigerant and compress it.

The manner of operation of glycol chillers is the same as that of ordinary air and drinking water-cooled chillers.

Chillers use a refrigerant gas to maneuver the unwanted heat among the evaporator as well as condenser. The chilled water is generated in evaporator which is distributed around the setting up by a pump to gather the undesired warmth and produce it back to the evaporator to become cooled down.

Air cooled chiller programs are much easier design and style and do not will need Yet another set of pumps for the condenser

Injection Molding – Injection molding can be a mass-output technique for developing plastic elements using an injection molding equipment, thermoplastic pellets, as well as a mould. The process and melt must be preserved inside specific temperature limitations to circumvent issues which include cracks, warping, and inner stresses in the ultimate merchandise.

Besides their cooling procedures, industrial chillers are categorized by the kind of compressor used. Though all compressors have the fundamental role of compressing the refrigerant to elevate its temperature and force right before reaching the condenser, they hire assorted models and operational mechanisms to accomplish this compression.

In certain techniques, if the cooling demand from customers is lower than the procedure’s ability, the control technique could “get rid of” load by turning off needless pumps or shutting airedale chiller spares down cooling models, cutting down the operational Electrical power usage

Being familiar with how an industrial chiller functions and the various forms of chillers available can help you choose the ideal cooling requires.

The main approach to categorise a chiller is by defining whether it is a vapor compression or vapor absorption form chiller.

Massive properties with cooling loads in extra of four hundred lots of refrigeration or one,400 kW generally use h2o cooled chillers with either centrifugal compressors or Turbocor compressors inside the central plant cooling technique. They could also use a separate more compact air cooled chiller to take care of the critical cooling loads including Computer system and interaction rooms.

For those who’re interested in chiller technologies then you ought to checkout the wide selection of Danfoss chiller answers at Chillers.Danfoss.com Danfoss has a large portfolio of items to aid all sorts of chiller techniques execute reliably and proficiently.

Within our prior movie we looked at chiller types and programs where by we covered the differing types of compressors, the programs and efficiency. Check that […]

A vapor-compression chiller uses a refrigerant internally as its Performing fluid. Numerous refrigerants selections can be found; when picking out a chiller, the application cooling temperature necessities and refrigerant's cooling characteristics must be matched. Important parameters to take into consideration would website be the running temperatures and pressures.

Matilda Ledger Then & Now!

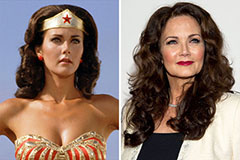

Matilda Ledger Then & Now! Lynda Carter Then & Now!

Lynda Carter Then & Now! Kane Then & Now!

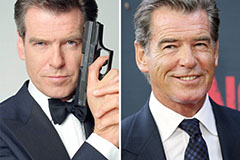

Kane Then & Now! Pierce Brosnan Then & Now!

Pierce Brosnan Then & Now! Ricky Schroder Then & Now!

Ricky Schroder Then & Now!